Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Wonke Electric CO.,Ltd.

With the increasingly frequent use of terminal products in the field of wiring, more and more users have put forward more requirements for them. For this reason, the structure and wiring methods of terminals have undergone great changes. From the initial single structure change, a variety of wiring structures are extended, which are classified into categories and suitable for various wiring environments, which greatly facilitates our use. At the same time, the structure of the Terminal Block is becoming more and more user-friendly, and the wiring speed is also greatly improved, which reduces the labor intensity of workers. At the same time, the reliability of the terminal blocks is getting higher and higher, the new production process and technical equipment are put into use, and the scientific production process and quality control methods have greatly improved the quality and life of the terminal blocks. With the increasing calls for environmental protection, the environmental protection requirements of terminals are very necessary. Halogen-free addition of flame retardants, non-toxic conductor insulators, and lead-free plating are all positive responses to this requirement.

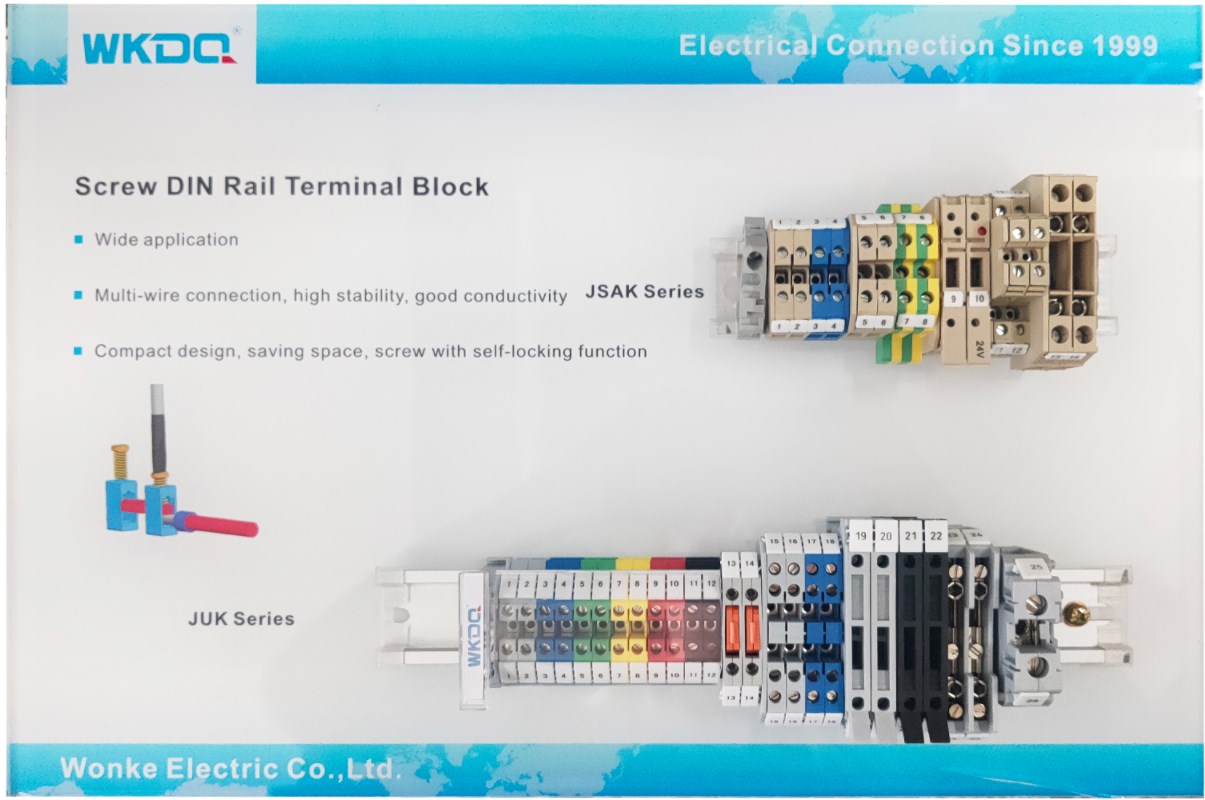

1. Screw terminal blocks:

Screw connection terminal blocks have always occupied an important position in the electronics industry, and now they have become an important component in the power industry. Its structural design takes into account the characteristics of convenient wiring and reliable screw connection.

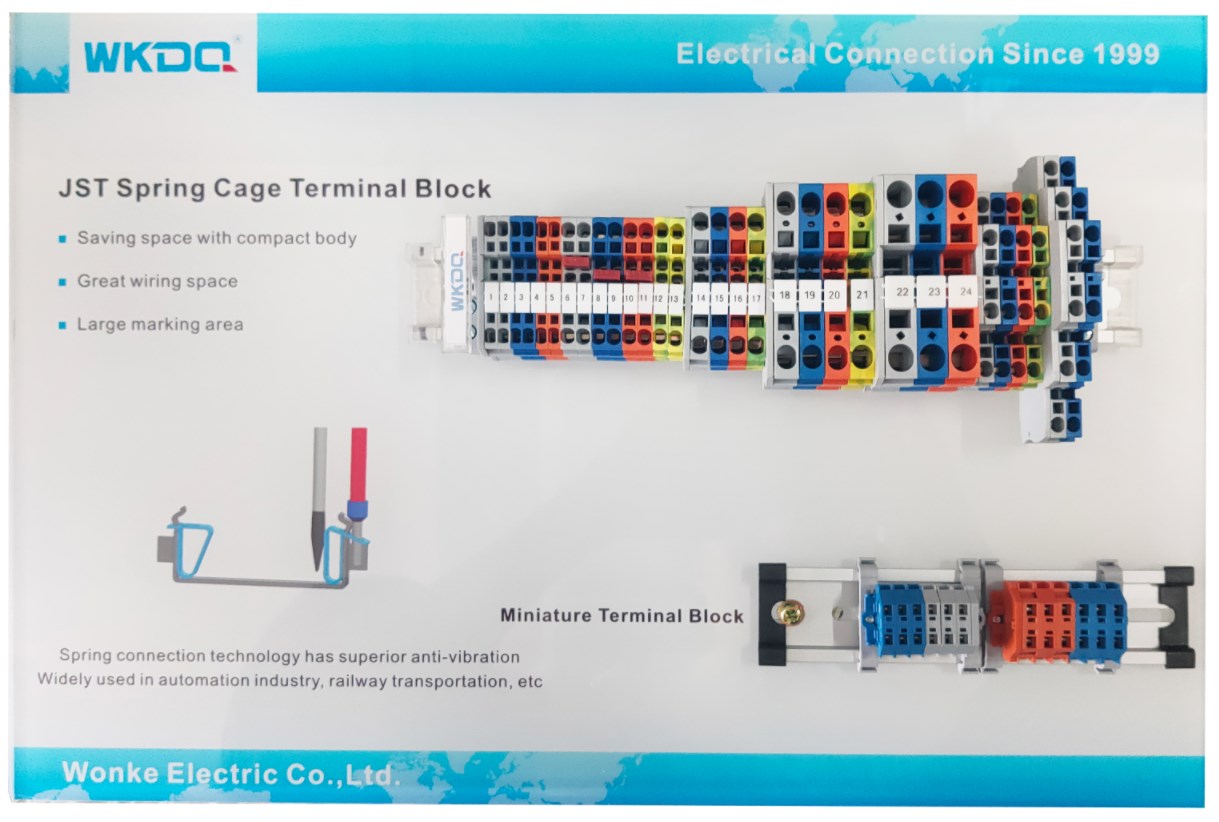

2. Spring-Cage terminal blocks

There are two types of connection methods for spring terminal blocks: pull-back spring connection and butterfly spring connection. Among them, the pull-back spring terminals and the screw terminals are compatible with each other, which greatly increases the flexibility. Reliable connection: front connection, connection is obvious, low maintenance, no tightening required.

3. Push in terminal blocks:

Rigid wires or flexible wires with ferrules are directly inserted into the wiring position, which is convenient and quick. The contact spring opens automatically, creating sufficient pressing force on the current bar. When installing thin conductors with a wire diameter of 0.14 mm² or more, use a standard screwdriver to unscrew the contact spring. Compared with Screw Terminal Blocks, it reduces installation time and insertion force by 50%, and can be wired without tools. In-line connection is a safe, reliable, simple and fast wiring method

4. Terminal Block Insulator Material

Material nylon (PA66), flame retardant grade V0, and does not contain any harmful halogens, excellent flame retardant performance, safety, and environmental protection. Other commonly used materials include thermoplastic polyester (PBT); and liquid crystal polymer (LCP) used for perforation reflow technology

The plastic insulating material and conductive parts of the terminal are directly related to the quality of the terminal, and they determine the insulation performance and conductivity of the terminal respectively. Failure of any terminal will lead to failure of the entire system engineering. The painful lessons that have happened at home and abroad in this regard are very profound.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.