Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Wonke Electric CO.,Ltd.

While components are ever increasingly being integrated into single packages such as SOCS and single-board computers, it can be argued that one component type, connectors, will always be around. In this article, we will learn the basics of connectors, why choosing the right one is vital for any design and some common examples of terminal blocks.

While electronic circuits can process signals and produce outputs, they almost always need to be connected to external components, power sources, inputs or outputs. These connections are done with the use of connectors, and they come in many different types, shapes, sizes and ratings. Choosing the wrong connector for your design can cause a range of issues, from bulky product sizes to components catching fire, so understanding the different types of connectors is imperative. And while there are many connector types available (pin headers, sockets, DIN and DB, for example), this article will focus on terminal blocks specifically, since they are found in just about every single sector, ranging from domestic wiring to industrial rack systems connecting to various I/O.

Terminal blocks are connectors that terminate a single wire and connect it to a circuit or other system. Terminal blocks come in a range of shapes, sizes and ratings, but always terminate a single wire (single pole) and are never multi-pole.

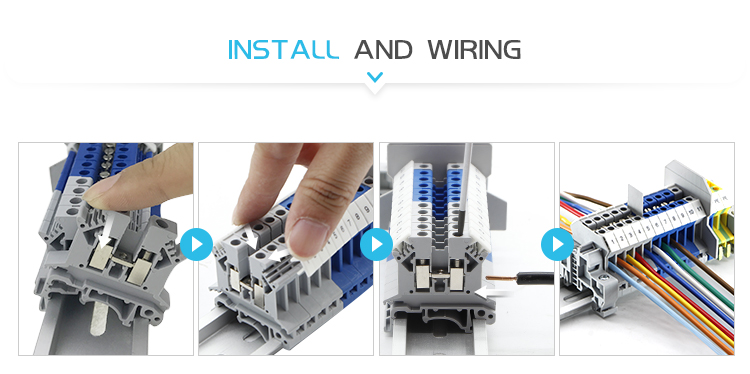

Terminal blocks are available as rows, but each terminal connects to only a single wire. Terminal Block connectors are very useful in situations that require semi-permanent connections, which may require inspections, wire replacement, repair and change (this is why terminal blocks are incredibly common in domestic wiring and industrial environments). While not all terminal blocks have PCB contact pads or legs, they always have some mechanically solid body made of plastic or other insulating material.

The most common connection method for terminal blocks is the use of a screw, wherein wires are inserted and then clamped down with the use of a single screw. Larger terminal blocks used with large cables typically have the screw pushing the wire against a metal body, whereas terminal blocks used with thinner wire use a screw that pushes down on a lever or flat head that compresses the wire against a metal insert. Other terminal blocks may use screw-less levers, which can be thought of as a fish trap; the wire is inserted and the lever comes down, which prevents the wire from being pulled back out. Another terminal type are terminal blocks with screws for holding an inserted cable on one end and a plug on the other end so that the block can be inserted into a female connector (this allows for hot-swapping).

Screw Terminal Blocks are those that have a screw as the method for holding a cable or wire. It is more common to see screws have flat-head fittings, and these types of terminals are often found in situations in which voltage and current demands will be moderate (domestic/commercial wiring). While wires bound to a terminal block are not physically bonded with the use of solder, they are incredibly strong if done correctly and can be used in permanent scenarios. Great care should be taken when tightening terminal blocks because over-tightening can damage the inserted cable and result in an unreliable and potentially dangerous connection.

Barrier Terminals

Barrier terminals are very similar to screw terminals in that they use screws as the mechanism to hold cables. Barrier terminal blocks often have more than one termination point for multiple cables and, because of this, have small barriers between individual terminals. Barrier terminals can also have small lids and enclosures to further protect cabling and are commonly found in domestic wiring and other high-voltage scenarios that need to prevent arcing or potential short-circuits.

Push-fit terminal blocks use small spring-loaded levers that allow cables to enter the terminal block in one direction but do not allow them to leave, effectively holding the wire in place; hence, the name [push-fit."

This type of connector has some advantages over screw terminals in that they prevent over-tightening, but as a result, the designer is reliant on the spring having enough force to keep the wire in contact with the conductive body. Another issue with push-fit terminals is that some are not designed to be reused and lack a removing lever, which makes repair work difficult because whole terminals may need replacing.

Pluggable terminals

Pluggable terminal blocks are those that have a cable entry to allow the connection of a wire or cable but a plug output to allow for easy connection to a socket. These types of terminal blocks are very useful in situations in which hot-swapping may be important or a connection is expected to be removable for servicing or inspecting. Screw contacts are the most common type of connection method for inserted cables, but the screw often has a small metal plate attached to the end, which allows for gripping of both small and large cables.

Choosing the right type of connector for your application may seem trivial but, in fact, is more complex than you may realize. The aspects of terminal blocks that need to be considered are typically current requirements, voltage requirements, wire being used, mechanical strength and the environment.

Current requirement

Current requirements are arguably the most important aspect to consider because pushing too much current through a terminal block can result in overheating and, therefore, the destruction of the terminal block. When looking for a terminal block, be sure that the chosen block can, in fact, handle the current that you expect to use plus 50 percent more. For example, if an expected current of 2 A is to be drawn from a block, then a terminal block with a current rating of 3 A would be sufficient.

Voltage requirements

Just like current draw, voltage also needs to be taken into account. Voltage causes problems with dielectric breakdown such that a voltage too high for a terminal block could cause current leakage between adjacent terminal blocks. However, high voltage requirements are often rare in design, which is why voltage considerations are typically ignored for voltages under 100 V. However, it is still important that this figure is checked before a terminal block is chosen!

Wire being used

Not all wires are equal, and each wire type has its own advantages and disadvantages. For example, when choosing a terminal block for a cable, be sure to know the size of the cable (can it physically fit into the terminal block?) as well as if it`s single-core or multi-core. Multi-core wire does very well in screw terminals, whereas single-core wire does well in push-fit connectors.

Environmental/mechanical strength

The environment is a very important aspect to consider when choosing a terminal block. Some terminal blocks may be mechanically strong and able to handle high currents, but if the connection is being used in a naval environment, then the salty air could be detrimental to the metal contacts. The environment could also have wide temperate swings or contain mechanical vibrations, which make screw terminations unreliable.

Terminal blocks are used in many designs and choosing the right one is very important. Learning to recognize the different types of connectors and their advantages and disadvantages can save designers time and money by understanding what their product is, what it will experience and in what environment it will be used.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.